MULTIDESK

MultiDesk is specialist in het verwerken van houten plaatmateriaal voor horizontale en verticale toepassingen.

Als toeleverancier van bureau- en werkbladen alsmede gevelplaten aan de industrie, bouw, interieur en exterieur en de projectmeubelmarkt zijn wij zeer allround ingericht.

Wij beschikken over een veelzijdig machinepark van een automatisch platenmagazijn met daarin geïntegreerd twee opdeelzagen,

fineerafdeling waar we zelf snijden en voegen, een perserij, freesafdeling en een spuiterij.

Bij de productie is een onbeperkte vorm en materiaalkeuze mogelijk en wordt probleemloos gecombineerd met fineer, compact,

HPL, marmoleum, desktop en diverse duurzame (plaat)materialen.

AUTOMATISCH PLATENMAGAZIJN MET GEÏNTEGREERDE OPDEELZAGEN

Door ons automatisch platenmagazijn met daarin geïntegreerd twee opdeelzagen zijn wij in staat om in zeer korte tijd grote hoeveelheden plaatmateriaal te verwerken. Middels optimalisatiesoftware kunnen wij het rendement van een plaat maximaal benutten. Dit geldt ook voor kleinere hoeveelheden of repeterend stuks werk.

Onze opdeelzagen kunnen platen met afmetingen t/m 4200 x 4200 mm verwerken. Als moederplaat werken wij veel met de maat 5600 x 2440 mm die wij op gewenste zaagsnede laten binnenkomen om deze vervolgens verder te optimaliseren. Kortom, u wordt bij ons in maatvoering niet beperkt tot de bekende handelsmaten.

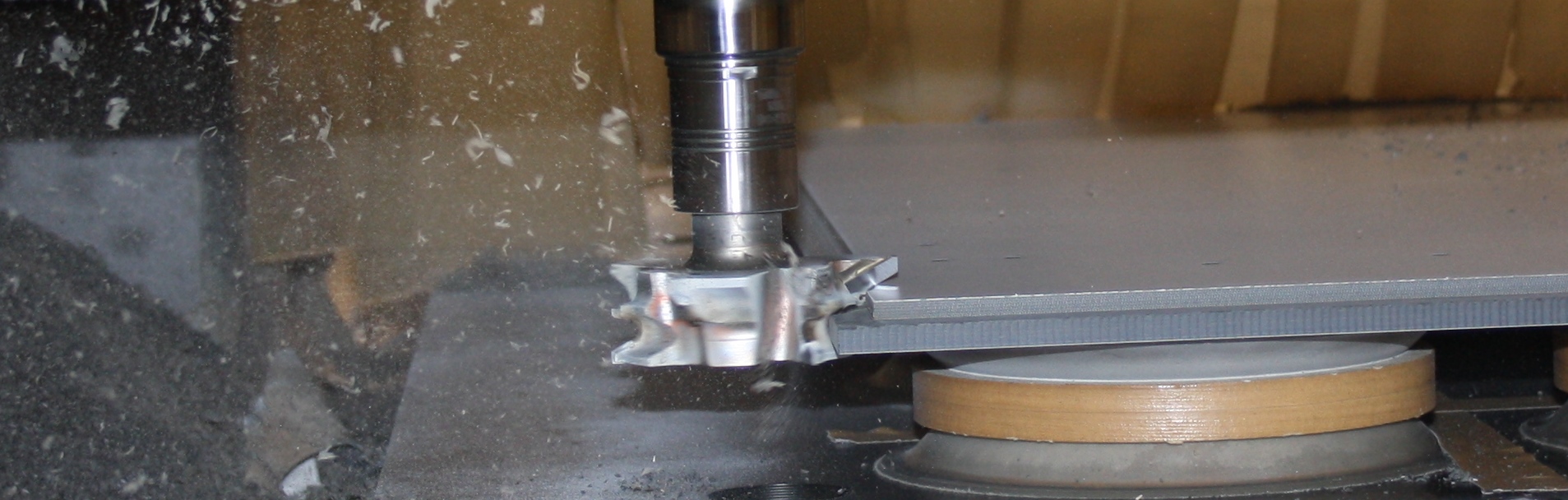

CNC FREZEN

Onze CNC freesmachines zijn in te delen in twee categorieën: 2,5 D en 3D frezen.

2,5D frezen

Onder 2,5D frezen verstaan wij onder ander het reguliere CNC frezen, point-to-point boorwerk en het aanbrengen van ABS kanten in organische vormen. Dit is mogelijk op één en dezelfde machine.

MultiDesk richt zich op het frezen, boren en kanten aanlijmen aan diverse plaatmaterialen. Dit zijn onder andere: Bamboe, MDF/ HDF, Spaanplaat, Berken, Beuken en populierenmultiplex, Massief hout, (Compact) HPL en alle soorten beplakte plaatmaterialen.

3D frezen

Behalve het frezen van contouren uit plaatmaterialen kunnen wij ook 3D vormen aanbrengen in plaatmateriaal. Hiervoor gebruiken wij 5-assige freesmachines. Zo zijn wij in staat allerlei contramallen, CNC mallen, gietmatrijzen en/ of modellen te frezen.

FINEREN

Wij fineren panelen met allerlei verschillende houtsoorten. Hierbij zijn vorm en maatvoering doorgaans onbeperkt. De gefineerde panelen werken wij af tot het door u gewenste eindproduct.

Kernmateriaal

Alleen het fineer is nog geen paneel of bureaublad. De gekozen ondergrond oftewel ‘drager’ is minstens zo belangrijk, deze heeft een grote uitwerking op de kwaliteit van het eindproduct. Geschikte plaatmaterialen zijn: MDF, Berken-, beuken-, populierenmultiplex en spaanplaat.

Fineer is ook geschikt om te lasersnijden en/of lasergraveren!

LASERGRAVEREN EN LASERSNIJDEN

Lasergraveren is een mogelijkheid om uw producten te onderscheiden. Het is mogelijk uw product te voorzien van tekst, een codering of bijvoorbeeld uw logo.

Wij kunnen de volgende materialen voor u laseren: HPL, Fineer, Multiplex, MDF, Glas, Metaal, Melamine en Karton. Veel van deze materialen kunnen wij ook lasersnijden.

Lasersnijden

Wilt u letters uitsnijden of uw logo gebruiken voor plak- of spuitwerk, dan kunnen wij dit voor u lasersnijden in karton, HPL, fineer of multiplex en MDF tot 3mm dikte.

LASER EN PU-KANTAANLIJMING

Randafwerking van plaatmateriaal, panelen, tafels of bureaubladen zijn bij MultiDesk zeer divers.

Specifiek voor kantaanlijming beschikt MultiDesk over zowel een laser- als PU verlijmingsmachine voor kanten. PU verlijming is een watervaste verlijming van hoogwaardige kwaliteit. Door de toepassing van het juiste laserkantenband en/of PU verlijming ontstaat een naadloze overgang tussen de top en de rand van het product, de optische nulvoeg.

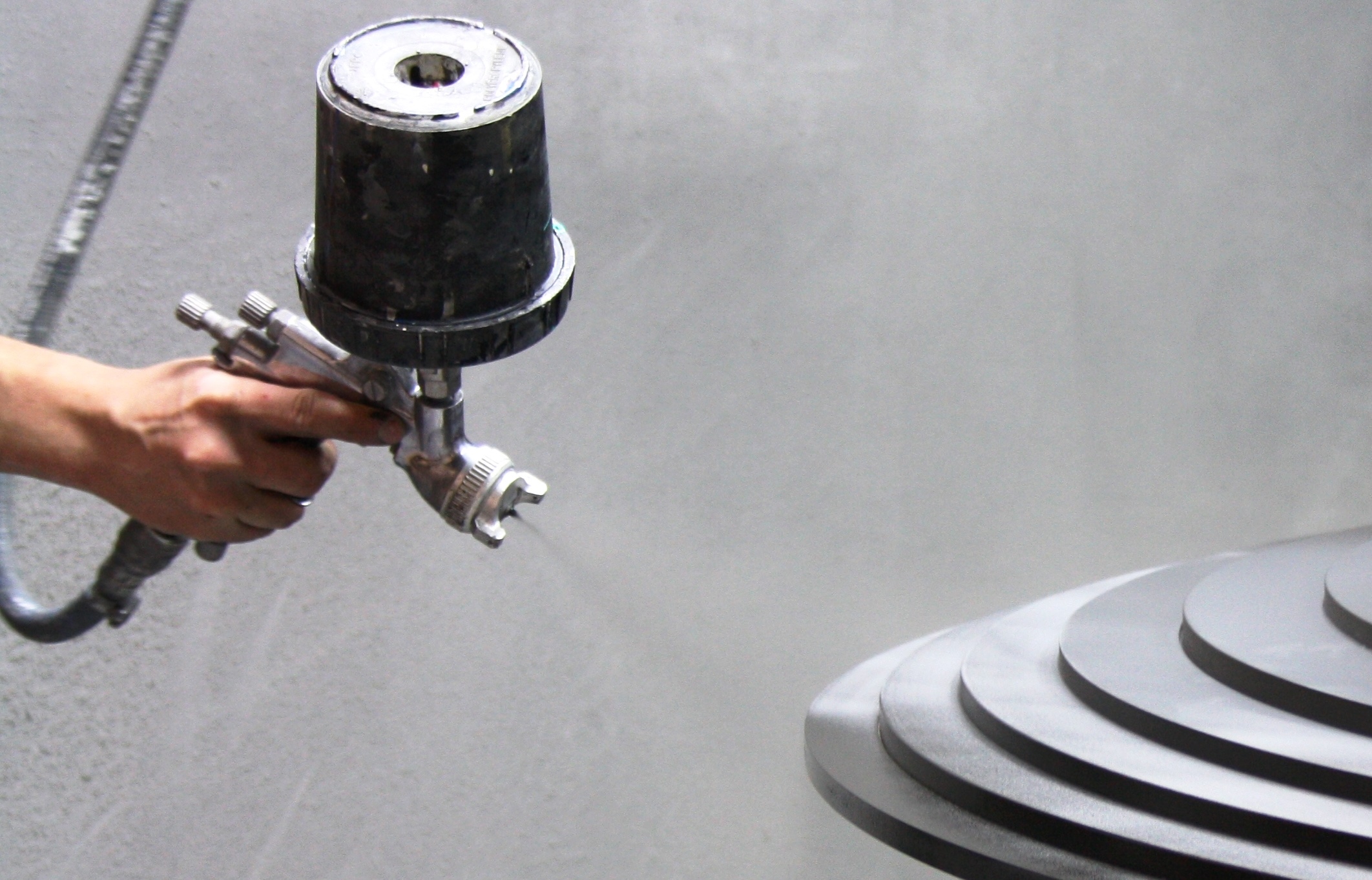

KLEURLAK SPUITEN EN HOOGGLANS LAKKEN

Uw materialen worden conform de gewenste kleur en bijbehorende glansgraad gespoten. Voor de juiste kleur maken wij gebruik van de coderingen RAL, Sikkens en NCS codes. Daarnaast kunnen wij alle kleuren zo exact mengen, dat er een voor u unieke kleur ontstaat.

De glans van de lak die wij standaard aanbieden ligt tussen de 5 en 95. Voor glansgraden hoger dan 95, hoogglans, maken wij graag voor u een proef om samen te bepalen welke kwaliteit u verwacht voor uw producten.

De meest gevraagde hoogglans afwerkingen zijn in te delen in 3 categorieën: standaard hoogglans spuiten, hoogglans lakken en piano kwaliteit. Sinds kort hebben we een spuitrobot, hiermee verhogen we onze kwaliteit en kunnen we meer oplossingen aanbieden.

Adres

MultiDesk Productie B.V.

+31 (0)345 – 545 777

info@multidesk.nl

BTW nr NL808051611B01

KvK nr 20094230

Van Drenth Buighout

+31 (0)345 – 514 641

info@vandrenth.com

BTW nr NL005208452B01

KvK nr 11014344